R&D Lab Collection

- Nov 05, 2018

- Celebrate

- 4 minutes read

Meet the team that makes the impossible possible!

The world’s first coloured circulation coins. 3D coins with moving parts. Bi-metal coins that stand up to the demands of circulation. The Royal Canadian Mint has a long history of pushing the boundaries of minting technology. So how do those innovations come to be? Chief Technology Officer Dr. Xianyao Li offers a rare behind-the-scenes perspective on the Mint’s approach to R&D — and talks about the unique new R&D Lab Collection.

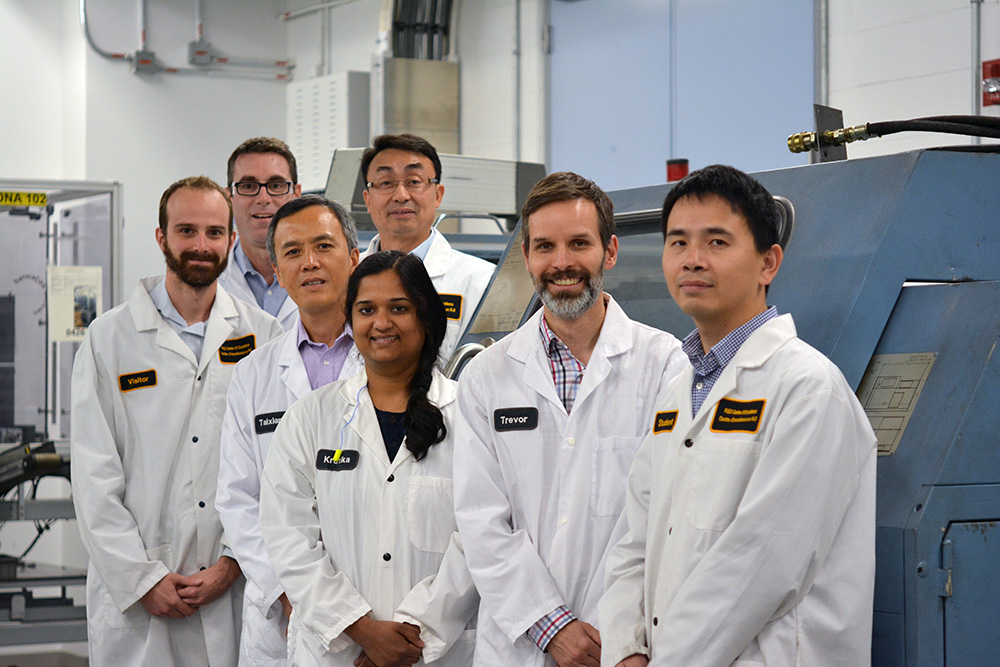

Li heads up a team of more than a dozen mechanical engineers, chemical engineers, metallurgical engineers and electrical engineers who make the magic happen.

“We all really enjoy the challenge of creating something new,” Li says. “There’s nothing like the excitement of achieving a goal you at first might have thought was totally not possible! I’m proud to be part of a talented team that isn’t afraid of taking risks.”

Meet the team that makes the impossible possible!

The world’s first coloured circulation coins. 3D coins with moving parts. Bi-metal coins that stand up to the demands of circulation. The Royal Canadian Mint has a long history of pushing the boundaries of minting technology. So how do those innovations come to be? Chief Technology Officer Dr. Xianyao Li offers a rare behind-the-scenes perspective on the Mint’s approach to R&D — and talks about the unique new R&D Lab Collection.

Li heads up a team of more than a dozen mechanical engineers, chemical engineers, metallurgical engineers and electrical engineers who make the magic happen.

“We all really enjoy the challenge of creating something new,” Li says. “There’s nothing like the excitement of achieving a goal you at first might have thought was totally not possible! I’m proud to be part of a talented team that isn’t afraid of taking risks.”

ALL IDEAS ARE WELCOME

The Mint accepts ideas and suggestions from all quarters. That includes ideas from senior executives and customers talking to salespeople.

The spirit of inclusivity is one of the things that motivates Product Engineer Christian Brochu.

“Listening to other people’s ideas and feedback helps us come up with better ways to do things,” Brochu says.

One of everyone’s favourite ways to get those ideas is the annual “Show Me the Money” event hosted by the Marketing and Product Development teams, where all employees are invited to submit their concepts for new coins. Suggestions are sorted and assessed to determine which are most innovative, marketable and technically feasible. The Mint teams also assess what kinds of risks might be involved. For Li’s team, the top priorities are always to make sure they can produce innovative coins cost-effectively and securely.

Their efforts have led to some of Canada’s — and the world’s — most exciting minting advances, including glow-in-the-dark coins, coins with extreme shapes, even a working carousel.

Li recalls that some technologies have had... unexpected impacts in the marketplace. The 2004 poppy coin commemorating Canada’s war veterans — the world’s first coloured circulation coin — was so unfamiliar to U.S. army contractors that they became suspicious and filed confidential espionage reports and prompted U.S. Department of Defense warnings that the coins might be some form of spyware.

SPOTLIGHT ON INNOVATION

With most innovative coins, the public sees the results once Li and his team have perfected them. But the R&D Lab Collection’s new Security Token Test Set showcases experimental coins at intermediate steps, with a focus on security technologies. Each of the six tokens is an actual test specimen used in laboratory and calibration testing, with novel security features including raised and incused design elements, visible and hidden microtext, and a new, patented method of fusing three metals into one coin.

Li says the tri-metal structure was particularly challenging. It was inspired by the popular bi-metal structure used for the Canadian $2 circulation coin. For that coin, the challenge was to lock the pieces firmly enough that they wouldn’t come apart in use. The tri-metal coin had the added requirement of fusing the two stacked inserts of the centre section to a common outer ring. Li’s team not only figured out how to do it, but were able to get it done at production speed — more than 400 coins per minute.

The second offering in the R&D Lab Collection is the $1 Pure Silver Double Concave Piedfort. It uses a brand-new minting technology to present the familiar loonie design in a way you’ve never seen it. “The first thing people will notice is how beautiful it is,” says Li. “But then they’ll wonder, ‘how did they do that?’”

“That” is a concave curvature of more than 6 mm on each side, for a total edge thickness of more than 16 mm. The extreme curvature of this design is meant to showcase the engineering feat required to push that much material to the edges while still producing a perfect, clean edge. Only 112 of these incredible coins were produced, and they sold out in less than two days.

Rapid sellouts are nothing new for the Mint, with many of their especially spectacular coins achieving that feat. But that doesn’t diminish the pride Li’s team feels when their creations do well.

Product Engineer Justin Deveau points to the Pure Silver Gold-Plated Antique Carousel coin as an example: “Part of our job is to think outside the box and develop novel coins,” he says. “I am proud to have contributed to such a technically challenging coin. And to top it off, people loved it!”

For Li, one of the projects he’s most proud of was the Mint’s Million Dollar Coin, a 99.999% pure gold bullion coin weighing in at 100 kg. The coin was certified in 2007 by Guinness World Records as the world’s largest and purest gold coin, and to date, five of them have been purchased by Canadian and international investors.

LOOKING AHEAD TO COINS OF THE FUTURE

Li and his team can’t wait for the next challenges in the future of minting. They’re proud to be at the vanguard of minting technology, and for many of them, that’s one of the best things about their jobs.

“To be working toward something that is first of its kind is exciting,” says Research Engineer Krutika Vishwakarma.

While they’re not spoiling any surprises about what they’re working on right now, the Mint’s R&D team is keeping a close eye on a few developing fields, including artificial intelligence and 3D printing. These technologies are making their marks on all kinds of industries, and Li expects it’s only a matter of time before someone — maybe someone on his team — figures out how to incorporate them into coin minting.

Thanks to a foundation of interdepartmental collaboration and strong support from Senior Leadership, we can look forward to many more exciting developments from the Mint.

“Management has a lot of faith and trust in innovation,” notes Li. “With their strong support for innovation, we’ll continue to push the envelope and do great things.”